They say, “you get what you pay for” and in this case, no words have been truer. When it comes to building materials, hollow blocks have always been the top choice because we’ve been using them for who knows when. But what if I tell you that there’s a better option? An option that will prove to be more efficient as materials are not only more durable but can come off as cheaper overall. These are just two of the many benefits of switching from hollow blocks to prefabricated materials.

What Are Prefab Materials?

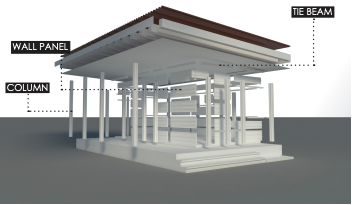

This simply means that materials are manufactured beforehand; Construction materials, usually consisting of concrete, steel, or wood (varies depending on the requirements of a project) built in a controlled atmosphere, like a warehouse or manufacturing plant.

Here in the Philippines, we’ve seen a boom in prefab projects ranging from houses, fences, warehouses, and other installations. Instead of building block per block laying the batter boards, the blocks per piece, and curing concrete; prefabricated materials are already manufactured in a factory. They’re built off-site and ready for delivery straight to the project site where they are either built per section or assembled as a whole.

Benefits

The benefits of using prefabricated materials are endless! Let me give you a quick rundown of just how efficient these materials can be.

Affordability: Now this will vary depending on the prefab materials that will be used for the project, however, we do see a trend that since materials are already made, we eliminate a lot of third-party costs. Also, parts are manufactured in a controlled setting so there is no to minimal wastage when producing. Now, don’t be confused, of course, if you compare per piece, prefab materials may (or may not–again, depends on material) come out more expensive BUT factoring in the project’s overall cost as well as the savings you’ll get in manpower salary since the project will be completed a lot faster, then you see massive savings of at least 15%.

Mobility: Prefabricated materials are easy to assemble or install and can be disassembled and transferred to another location. This gives lot owners flexibility when it comes to using the materials. On top of this, expansions are something that is easily achievable with prefab materials since you can move the parts around.

Quality: Materials prove to be more durable since manufacturing them is standardized in a factory setting. They go through rigorous quality control checks and tests and they use standardized raw materials and components as well. Compared to your conventional backyard mix, prefab materials are measured and constructed to the T.

Turnover: Since most (if not all) materials are made off-site and ready for delivery and installation, assembly of the parts prove to be more efficient and a lot faster. This trims the construction time by as much as 30-50%.

Eco-friendly: Producing these materials entail a significant decrease in carbon footprint. It produces less waste compared to the conventional use of hollow blocks. On top of this, since most materials are transferable and reusable, there is little to no wastage.

The use of prefab materials has been around for years and consumer patronage has been steadily increasing. What’s important is to be able to consistently share the understanding and the benefits that in truth greatly outweighs other competitors in the market. Prefab materials are both sturdy and affordable; two great features that are perfect for a typhoon-stricken, third-world country like the Philippines. Going the pre-fab way is definitely more enticing. Do you want to know more about prefab materials? WallCrete Company Inc. manufactures the proven and trusted Vazbuilt System made from prefabricated concrete materials with one of the highest grades of PSI for fencing and housing needs.

No Comments Yet

Leave a Comment